×

❮

❯

![]()

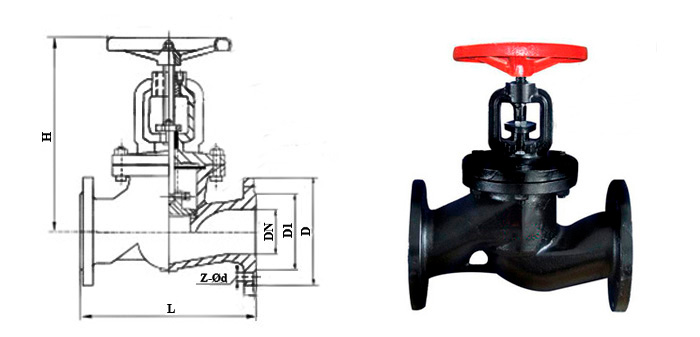

Cast iron flanged globe valve 15ch14br Pn 16

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 65 | 2266.00 | 8 | 0 | 12.8 |

| DN 80 | 3465.00 | 9 | 0 | 28.6 |

| DN 100 | 4263.00 | 14 | 0 | 36.0 |

| DN 125 | 6391.00 | 7 | 0 | 43.0 |

| DN 150 | 7321.00 | 5 | 0 | 57.0 |

| DN 200 | 14509.00 | 0 | 0 | 102.8 |

Cast iron globe valves 15ch14br (J41T-16) PN 16 belong to shut-off valves designed for completely blocking flow of the working medium in pipelines. They are used for transporting water and steam at temperatures up to +225°C. The main task of these valves is to provide a tight closure of the working medium flow, making them in demand in heating systems, water supply, and steam pipelines.

Marking of globe valve 15ch14br

- 15 – indicates that this is a globe valve.

- ch – indicates the body material (made of gray cast iron).

- 14 – this is the valve model number.

- br – indicates the type of sealing, in this case, bronze or brass.

Construction

The valve 15ch14br consists of the following main elements:

- Body: Made of gray cast iron.

- Seat: Overlaid with brass to ensure tightness.

- Spool: Made in the form of a disk fixed at the end of the spindle. It is parallel and coaxial with the seat.

- Spindle: Steel element with gland packing to prevent leaks.

- Sealing rings: Brass rings on the spool and body ensure tight fit of the parts.

- Wheel: Manual drive for controlling the valve.

Working principle

Operation of the globe valve 15ch14br is based on the movement of the spool relative to the seat:

- When the wheel is turned clockwise, the spindle goes down, pressing the spool against the seat. This completely blocks flow of the working medium.

- When the wheel is turned counterclockwise, the spindle rises, moving the spool away from the seat and opening passage for the working medium.

Operational features

- The valve is installed on the pipeline in any working position. It is important to observe the direction of the working medium flow according to the indicator on the product body.

- Before installation, it is necessary to rinse and blow out the product to remove contamination.

- Regularly inspect the spindle for leaks:

- If leaks are detected, tighten the gland or replace the gland packing.

- To prevent corrosion, it is recommended to lubricate the spindle, which also improves the smoothness of the handwheel.

Advantages

- High tightness due to brass sealing surfaces.

- The simplicity of the design ensures ease of maintenance and repair.

- Durability under operating conditions (average resource – 1600 cycles).

| DN | L | D | D1 | H | Z-Ød |

|---|---|---|---|---|---|

| 65 | 290 | 185 | 145 | 341 | 4-18 |

| 80 | 310 | 200 | 160 | 385 | 4-18 |

| 100 | 350 | 220 | 180 | 385 | 4-18 |

| 125 | 400 | 250 | 210 | 471 | 4-18 |

| 150 | 480 | 285 | 240 | 516 | 8-22 |

| 200 | 600 | 335 | 295 | 610 | 12-23 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | фланцевый |

| Working environment | water, steam |

| Maximum working environment temperature, °C | 225 |

| Sealing class | A |

| Body strength test, MPa | 2.4 |

| Sealing tightness test, MPa | 1.8 |

| Description | Material |

|---|---|

| Stem | Carbon steel |

| Shutter (Disc) | Cast iron + brass |

| Body | Cast iron |

| Sealing ring | Steel + graphite |

| Bonnet | Cast iron |