Cast iron flanged globe valve 15ch16p(ft) Pn 25

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 32 | 2000.00 | 0 | 0 | 8.3 |

| DN 40 | 2350.00 | 102 | 0 | 9.8 |

| DN 50 | 3250.00 | 45 | 0 | 14.45 |

| DN 65 | 4500.00 | 0 | 0 | 20.4 |

| DN 80 | 5800.00 | 0 | 0 | 28.8 |

| DN 100 | 6500.00 | 0 | 0 | 39.5 |

Cast iron flanged globe valves 15kch16p(ft) PN 25 MPa are devices designed to regulate or completely shut off flow of the working medium in pipelines. The valves are designed to operate with water or steam at temperatures up to 225°C.

Marking of globe valve 15kch16p(ft)

- 15 – indicates that this is a globe valve.

- kch – material of the valve body, in this case, ductile iron.

- 16 – model number of the valve.

- p(ft) – type of sealing, in this case, made of paronite or fluoroplastic.

Main components of globe valve 15kch16p(ft)

- Body and Cover:

- Body and cover of the valve are made of high-strength cast iron.

- Body has flanged connections for installation on the pipeline.

- Shut-off Element (Spool):

- The spool is responsible for closing or opening the passage.

- It is made of cast iron with sealing surfaces made of paronite or fluoroplastic to ensure tightness.

- Spindle:

- The spindle is made of steel.

- It transfers the rotational motion from the wheel to the spool, ensuring its linear movement up or down.

- Wheel:

- The Wheel is used for manual operation of the valve.

- When the wheel is rotated, the spindle raises or lowers the spool.

- Stuffing Box Packing:

- Stuffing box packing ensures tightness around the spindle and prevents leakage of the working medium through the spindle exit point.

Operating principle

Operation of the valve is based on the linear movement of the spool:

- When the wheel is rotated, the spindle begins to move up or down.

- This movement raises or lowers the spool, which either completely shuts off flow of the working medium through the body seat or opens it.

- Direction of the working medium flow must match the direction of the arrow marked on the valve body.

Advantages of globe valves 15kch16p(ft)

- High tightness due to high-quality sealing materials.

- Ease of maintenance and repair due to the dismountable design.

- Long service life when operating conditions are observed.

- Versatility in installation on pipelines of various purposes.

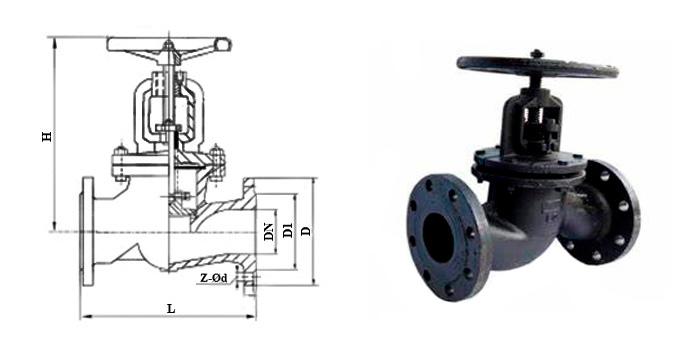

| DN | L | D | D1 | H | Z-Ød |

|---|---|---|---|---|---|

| 32 | 180 | 135 | 100 | 250 | 4-18 |

| 40 | 200 | 145 | 110 | 288 | 4-18 |

| 50 | 230 | 160 | 125 | 321 | 4-18 |

| 65 | 290 | 180 | 145 | 341 | 4-18 |

| 80 | 310 | 195 | 160 | 385 | 8-18 |

| 100 | 350 | 215 | 180 | 437 | 8-18 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 2.5 (25) |

| Connection type | фланцевый |

| Working environment | water, steam |

| Maximum working environment temperature, °C | 225 |

| Sealing class | A |

| Body strength test, MPa | 3.8 |

| Sealing tightness test, MPa | 2.8 |

| Description | Material |

|---|---|

| Body | Ductile Iron |

| Sealing ring | Steel + graphite |

| Bonnet | Ductile Iron |

| Stem | Carbon steel |

| Shutter (Disc) | Ductile iron + PTFE |