×

❮

❯

![]()

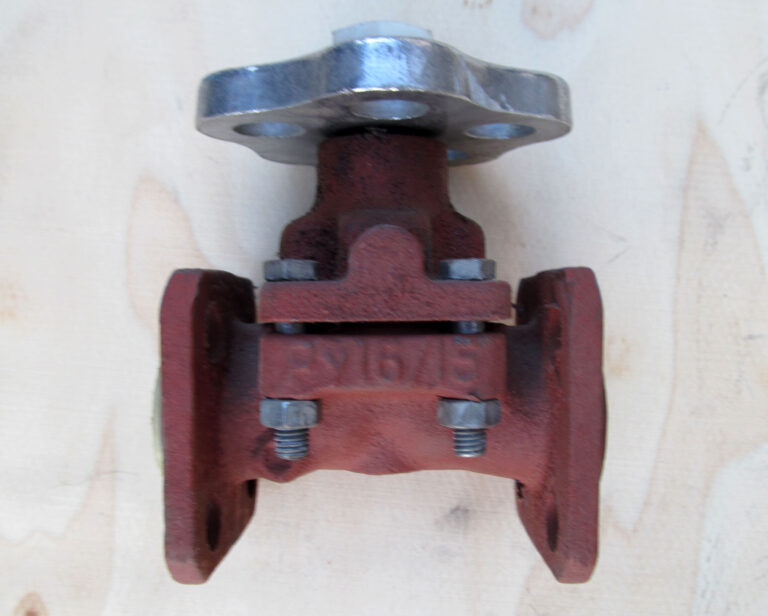

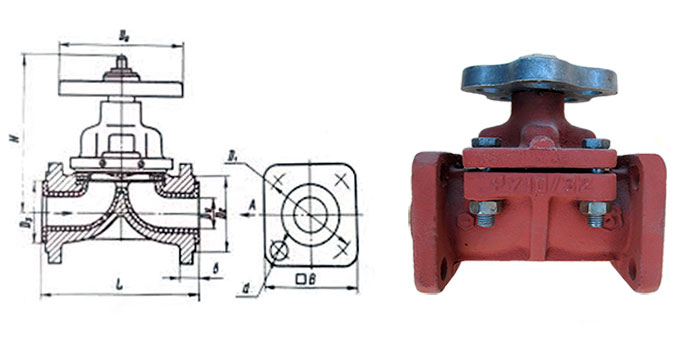

Diaphragm globe valve 15ch75p2 lined with PTFE Pn 10

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 15 | 3069.00 | 33 | 0 | 3.0 |

| DN 25 | 3801.00 | 2 | 0 | 6.1 |

| DN 32 | 4389.00 | 16 | 0 | 8.0 |

| DN 40 | 5407.00 | 3 | 0 | 12.6 |

| DN 50 | 6732.00 | 0 | 0 | 14.0 |

Cast iron diaphragm globe valves 15ch75p2 PN 10 lined with fluoroplastic are used as shut-off devices on pipelines. Thanks to the fluoroplastic lining, valves have high resistance to chemically aggressive environments, such as acids and alkalis. Main purpose of the 15ch75p2 valves is to be used in pipeline systems with corrosive environments, provided there are no solid inclusions.

Globe valves 15ch75p2 can operate with the following working environments at a working medium temperature of up to +110°C:

- Nitric acid (up to 98% concentration);

- Sulfuric acid (up to 98%);

- Hydrochloric acid;

- Hydrofluosilicic acid;

- Acetic acid;

- Phosphoric acid;

- Hydrogen peroxide;

- Salt solutions;

- Bromine, chlorine, hydrogen chloride;

- Alcohols, glycerin, gasoline, kerosene, mineral oil.

Design and operational features

- Fluoroplastic lining: Provides high resistance to chemical influences and prevents the valve body from being damaged by aggressive environments.

- Manual operation: The flow is shut off by manually rotating the wheel:

- Clockwise – closing the valve.

- Counterclockwise – opening the valve.

- Installation position: The valve can be installed in any position on the pipeline, provided the direction of the working medium flow is observed (indicated by an arrow on the body).

- Maintenance: To ensure reliable operation of the valve, it is necessary to:

- Regularly check the tightness of connections and the condition of bolt fastenings.

- Lubricate the threaded part of the spindle.

- Disassemble the valve if necessary to eliminate defects, following safety precautions.

Applications

Globe valves 15ch75p2 are used in various industries for transporting aggressive chemical substances:

- Chemical industry;

- Petrochemical industry;

- Production of acids and alkalis;

- Laboratory installations;

- Systems for supplying alcohols or petroleum products.

Advantages of 15ch75p2 valve

- High corrosion resistance due to fluoroplastic lining.

- Simple design ensures reliable operation with minimal maintenance.

- Ability to be used with a wide range of aggressive working environments.

- Versatile installation – can be mounted in any position on the pipeline.

| DN | L | D1 | D2 | H |

|---|---|---|---|---|

| 15 | 130 | 65 | 36 | 105 |

| 25 | 150 | 85 | 58 | 140 |

| 32 | 170 | 100 | 66 | 145 |

| 40 | 190 | 110 | 76 | 190 |

| 50 | 200 | 125 | 88 | 190 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.0 (10) |

| Connection type | фланцевый |

| Working environment | acid, alkali, salt, aggressive liquids |

| Maximum working environment temperature, °C | 120 |

| Sealing class | A |

| Body strength test, MPa | 1.5 |

| Sealing tightness test, MPa | 1.1 |

| Description | Material |

|---|---|

| Body | Gray cast iron + Fluoroplastic |

| Diaphragm | PTFE |

| Bonnet | Grey cast iron |

| Stem | Carbon steel |