×

❮

❯

![]()

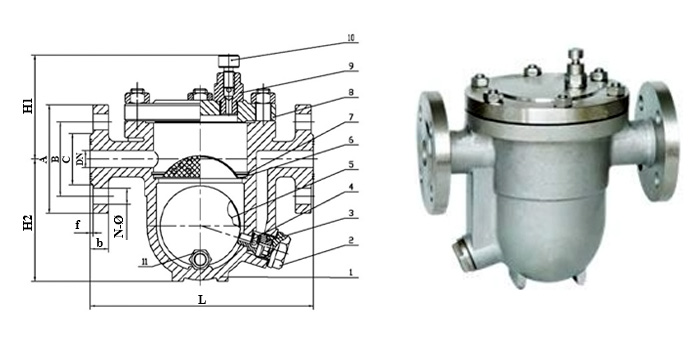

Flanged float steam trap Pn 16

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 25 | 4653.00 | 12 | 0 | 8.6 |

| DN 50 | 7194.00 | 17 | 0 | 26.5 |

Float steam traps are installed on steam pipelines and steam receivers to automatically remove condensate that forms in pipelines and heat exchange equipment. Their main task is to prevent accumulation of condensate, which can lead to decreased system efficiency, water hammer, and equipment damage. Principle of operation of these devices is based on the difference in density between steam and water. Steam trap is equipped with a float connected to a valve by a lever. When the condensate level in the chamber reaches a certain point, the float rises and opens the valve to drain the liquid.

Main advantages of using float steam traps

- Prevention of water hammer: Accumulation of condensate in steam pipelines can cause water hammer, which can damage pipes and equipment. Installing float steam traps eliminates this problem.

- Increased system efficiency: Removing excess condensate helps maintain optimal steam heat content.

- Equipment durability: Regular removal of moisture extends the service life of pipelines and heat exchangers.

- Versatility of application: Float models are suitable for various types of equipment, from heat exchangers to main steam pipelines.

Applications in various industries

Float steam traps are widely used:

- In heat exchangers;

- On main steam pipelines;

- In heating vessels;

| DN | L | b | H | H1 | Z-Ød |

|---|---|---|---|---|---|

| 25 | 215 | 16 | 102 | 112 | 4-14 |

| 50 | 290 | 20 | 117 | 175 | 4-18 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | фланцевый |

| Working environment | steam, condensate |

| Maximum working environment temperature, °C | 350 |

| Body strength test, MPa | 2.8 |

| Description | Material |

|---|---|

| Floating shutter | Stainless steel 304 |

| Air filter | Stainless steel 304 |

| Body | WCB |

| Bonnet | WCB |