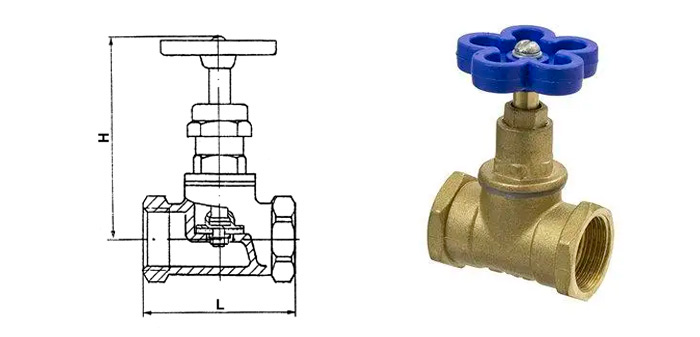

Brass globe valve 15b3r threaded Int/Int Pn 10

| Nominal diameter | Inches | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|---|

| DN 15 | 1/2" | 125.00 | 112 | 0 | 0.19 |

| DN 20 | 3/4" | 165.00 | 237 | 0 | 0.24 |

| DN 25 | 1" | 250.00 | 104 | 0 | 0.38 |

| DN 32 | 1 1/4" | 440.00 | 100 | 0 | 0.8 |

| DN 40 | 1 1/2" | 725.00 | 120 | 0 | 1.05 |

| DN 50 | 2" | 935.00 | 158 | 0 | 1.65 |

Brass globe valves 15b3r are shut-off pipeline valves designed to completely shut off the flow of the working medium. They are used in water supply systems, both cold and hot water, in residential, public and domestic facilities. The main area of application of valves is utilities and the construction sector.

Design and operating principle

Globe valve 15b3r consists of the following main parts:

- Body: made of high-quality brass by die casting.

- Bonnet: also made of brass.

- Spindle: a brass element that ensures the movement of the spool.

- Spool: a disk-shaped element that blocks the flow of the working medium when lowered.

- Sealing ring: made of rubber to ensure tightness.

The valve operates as follows: rotation of the wheel causes the spool to move up or down. When the spool is lowered, it is pressed tightly against the valve seat, completely blocking the flow of the working medium. To seal against the external environment, a gland seal with the ability to tighten the union nut is used.

Design Features

- Compact dimensions and light weight make the valve convenient for installation even in limited spaces.

- Easy replacement of worn parts of the valve due to the disassemblable design.

- High tightness of the valve is achieved by using a rubber seal on the spool.

Application limitations

- The valve is not suitable for aggressive environments or operating temperatures above +75°C.

- It is not recommended to use it as a control valve due to the risk of rapid wear of the sealing surfaces of the body and spool.

- If high throughput is required, it is better to replace the valve with a ball valve or a gate valve, which have lower hydraulic resistance.

Installation recommendations

Before installing the 15b3r valve, it is necessary to:

- Check the system pipes for contamination (e.g. sand or scale). If contamination is detected, remove it by blowing or wiping.

- Make sure that the flow direction of the working medium is correct according to the arrow on the valve body.

- Check the condition of the gland seal and, if necessary, tighten it before operation.

After installation, it is important to periodically check the condition of the seals and carry out preventive maintenance to extend the service life of the device.

*Int / Int - Internal/Internal Thread.

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.0 (10) |

| Connection type | муфтовый |

| Working environment | water |

| Maximum working environment temperature, °C | 75 |

| Description | Material |

|---|---|

| Body | Brass |

| Bonnet | Brass |

| Spool | Brass |

| Stem | Brass |

| Sealing ring | Rubber |