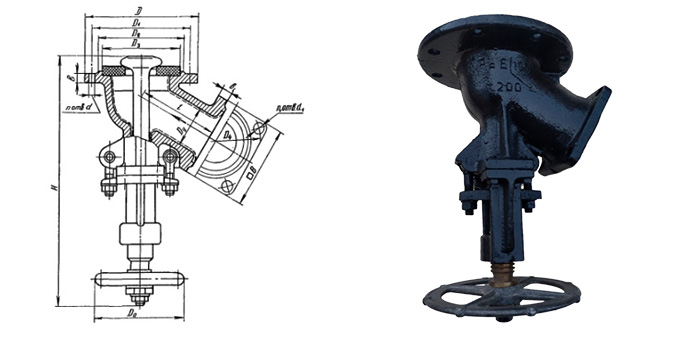

Enamel-coated corner type globe valve 15h47em shut-off bottom drain Pn 6

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 50 | 9500.00 | 0 | 0 | 8.8 |

| DN 65 | 10500.00 | 1 | 0 | 13.2 |

| DN 80 | 16000.00 | 0 | 0 | 19.3 |

| DN 100 | 21500.00 | 1 | 0 | 25.4 |

Enamel-coated globe valve 15ch47em (angle type) with bottom drain is used as a shut-off device on pipelines transporting aggressive working media. It is resistant to the action of most organic and inorganic acids (except hydrofluoric and fluosilicic), salt solutions of any concentration, as well as alkalis with pH below 11. Thanks to its protective enamel coating, the valve has excellent corrosion resistance and durability, making it in demand in the chemical, pharmaceutical, food and related industries.

The design of the valve is simple and reliable. The main parts are made from proven materials: the body and bonnet - from cast iron, the diaphragm - from fluoroplastic, the stem — from carbon steel, while the wheel and crosspiece are made from aluminium alloys. For improved tightness, bronze and brass bushings are used. Such a combination of materials ensures resistance to aggressive media, operational reliability, and ease of maintenance.

A special feature of the design is the bottom drain, which allows efficient removal of residual medium from the system and facilitates equipment flushing. This is especially important in cases where frequent product changes or strict sanitary standards are required.

Globe valves 15ch47em are available in nominal diameters: DN 50, 65, 80 and 100. The weight of the parts varies depending on the size, which should be taken into account when selecting.

Thanks to its characteristics, the 15ch47em globe valve is widely used in chemical production lines, laboratory installations, the pharmaceutical industry, as well as in enterprises where reliable shut-off or draining of aggressive liquids is required.

| DN | b | H |

|---|---|---|

| 50 | 110 | 327 |

| 65 | 125 | 357 |

| 80 | 140 | 395 |

| 100 | 150 | 478 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 0.6 (6) |

| Working environment | acid, alkali, salt, aggressive liquids |

| Maximum working environment temperature, °C | 200 |

| Description | Material |

|---|---|

| Shock absorber | 3826 |

| Stem | Carbon steel |

| Sleeve | Brass |

| Wheel | Aluminium alloy |

| Crosspiece | Aluminium alloy |

| Body | Cast iron |

| Bonnet | Cast iron |

| Diaphragm | Fluoroplastic |

| Nut | Brass |