×

❮

❯

![]()

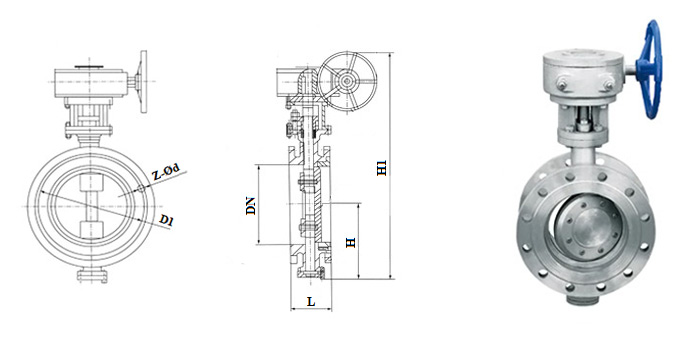

Flanged triple eccentric butterfly valve for manual or electric actuator Pn 16

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg | Electric actuator |

|---|---|---|---|---|---|

| DN 50 | 3450.00 | 28 | 0 | 8.0 | Q10 |

| DN 65 | 4000.00 | 19 | 0 | 9.0 | Q10 |

| DN 80 | 4500.00 | 15 | 0 | 10.0 | Q20 |

| DN 100 | 5700.00 | 18 | 0 | 13.0 | Q30 |

| DN 125 | 8000.00 | 16 | 0 | 16.0 | Q40 |

| DN 150 | 8950.00 | 50 | 0 | 25.0 | Q40 |

| DN 200 | 12500.00 | 11 | 0 | 35.0 | Q60 |

| DN 250 | 18200.00 | 16 | 0 | 50.0 | Z10 |

| DN 300 | 22500.00 | 16 | 0 | 70.0 | Z15 |

| DN 350 | 38000.00 | 2 | 0 | 100.0 | Z20 |

| DN 400 | 42500.00 | 4 | 0 | 110.0 | Z20 |

| DN 500 | 66800.00 | 2 | 0 | 175.0 | Z30 |

| DN 600 | 98500.00 | 4 | 0 | 275.0 | Z60 |

| DN 800 | 179500.00 | 2 | 0 | 550.0 | Z90 |

Steel flanged triple eccentric butterfly valves with stainless steel sealing PN 16, equipped with a manual actuator, are devices designed to shut off or regulate flow of the working medium in pipelines. Triple eccentricity is achieved through the following features:

- First eccentricity: Axis of rotation is offset relative to the center of the disc's sealing surface.

- Second eccentricity: Axis of rotation is tilted from the central axis of the pipeline.

- Third eccentricity: Conical shape of the disc ensures its displacement along a spheroid during rotation, eliminating contact between the sealing surfaces during opening/closing.

This design allows:

- Elimination of friction between the disc and the seat.

- Reduction of seal wear.

- Ensuring Class "A" tightness in both flow directions.

Advantages of triple eccentric flanged butterfly valves

- Durability: Minimization of friction increases the mechanism's service life.

- Low torque: Less effort is required to operate the valve due to reduced resistance during disc movement.

- Bidirectional tightness: The valve ensures complete shut-off of flow in both directions without leakage.

- Compactness and ease of installation: Small dimensions allow installation even in limited spaces without the need for large equipment.

- Cost-effective maintenance: The modular design facilitates the replacement of sealing elements both on-site and in repair workshops.

Areas of application

Triple eccentric flanged butterfly valves are used in various industries where high reliability and safety requirements are imposed:

- Oil production and refining

- Gas production and processing

- Chemical industry

- Metallurgy

- Thermal power engineering

| DN | L | D1 | H | H1 | Z-Ød |

|---|---|---|---|---|---|

| 50 | 108 | 125 | 112 | 350 | 4-19 |

| 65 | 112 | 145 | 115 | 370 | 4-19 |

| 80 | 114 | 160 | 120 | 380 | 8-19 |

| 100 | 127 | 180 | 138 | 420 | 8-19 |

| 125 | 140 | 210 | 164 | 460 | 8-19 |

| 150 | 140 | 240 | 175 | 555 | 8-23 |

| 200 | 152 | 295 | 208 | 605 | 12-23 |

| 250 | 165 | 355 | 243 | 680 | 12-28 |

| 300 | 178 | 410 | 283 | 800 | 12-28 |

| 350 | 190 | 470 | 310 | 835 | 16-28 |

| 400 | 216 | 525 | 340 | 915 | 16-31 |

| 500 | 229 | 650 | 410 | 1020 | 20-34 |

| 600 | 267 | 770 | 470 | 1225 | 20-37 |

| 800 | 318 | 950 | 640 | 1470 | 24-40 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | фланцевый |

| Working environment | water, steam, petroleum products |

| Maximum working environment temperature, °C | 425 |

| Sealing class | A |

| Body strength test, MPa | 2.4 |

| Sealing tightness test, MPa | 1.8 |

| Description | Material |

|---|---|

| Body | Steel |

| Stem | AISI 420 |

| Sealing ring | Stainless steel |

| Disk | Steel |