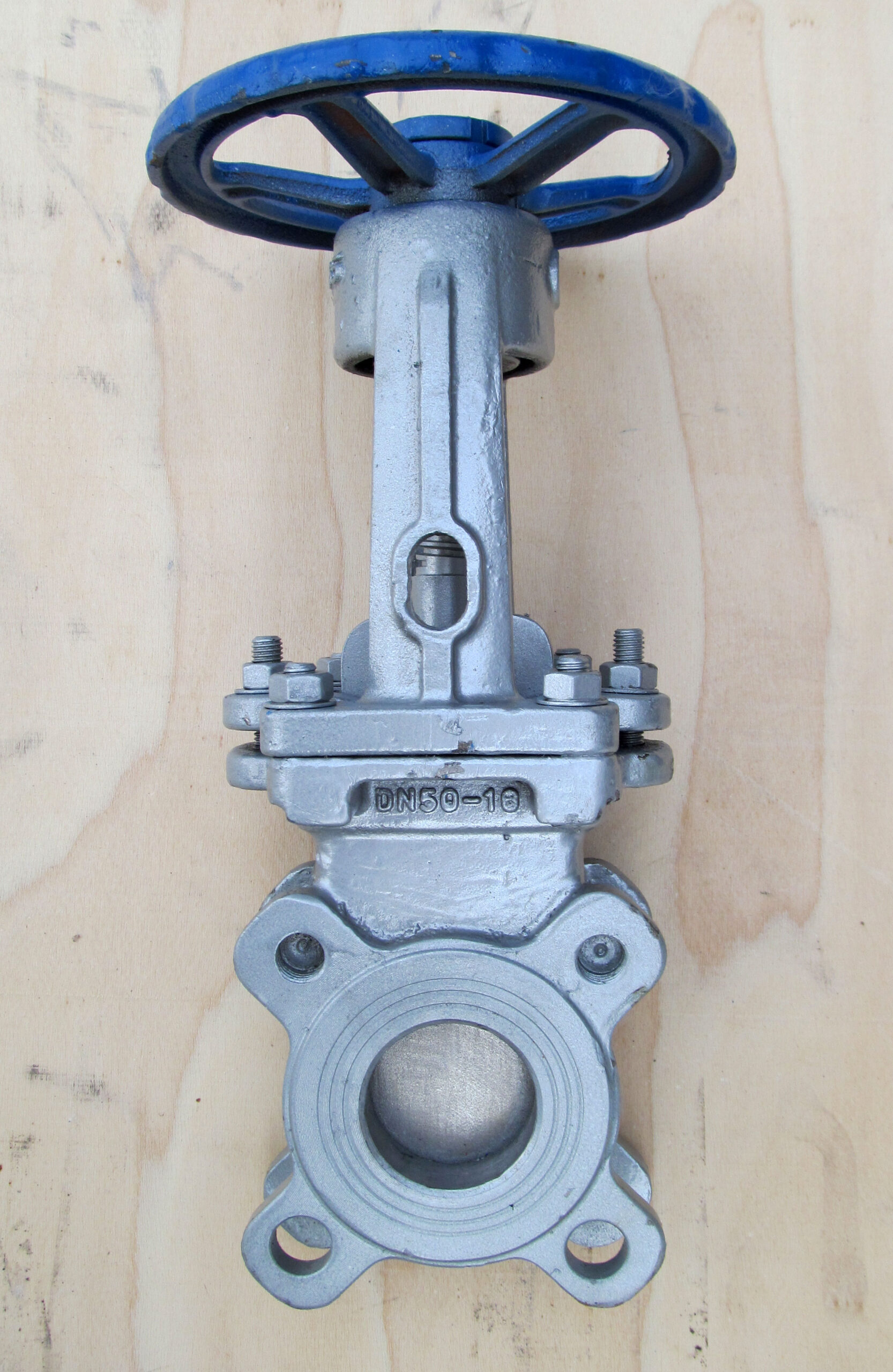

Steel knife gate valve Pn 16

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 50 | 4235.00 | 10 | 0 | 8.5 |

| DN 65 | 4719.00 | 0 | 0 | 10.7 |

| DN 80 | 5082.00 | 3 | 0 | 13.0 |

| DN 100 | 6655.00 | 0 | 0 | 15.0 |

| DN 150 | 10890.00 | 0 | 0 | 31.0 |

| DN 200 | 18150.00 | 0 | 0 | 40.7 |

| DN 250 | 30250.00 | 4 | 0 | 70.0 |

| DN 300 | 42350.00 | 0 | 0 | 107.0 |

| DN 350 | 66550.00 | 0 | 0 | 129.0 |

| DN 400 | 84700.00 | 0 | 0 | 215.0 |

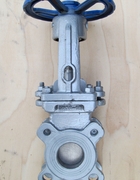

A knife gate valve is a type of pipeline valves in which the shut-off element (knife) is made in the form of a flat or wedge-shaped plate with parallel sealing surfaces. When operating, the knife moves perpendicular to the flow of the working medium, allowing complete shut-off or partial adjustment of the medium's flow in the pipeline.

Design and Main Components

- Knife (gate): The main element that directly blocks the flow.

- Rack and spindle with wheel: These elements convert rotational movement into linear movement of the knife, enabling quick opening or closing of the device.

- Seals and packing: Ensure the tightness of the unit, preventing leakage of the working medium.

- Body: Provides mounting of the valve on the pipeline.

Operating Principle

When the mechanism is activated, the knife moves along the guides inside the body. During movement, the flow is blocked:

1. Full closure – the knife completely blocks the pipeline, preventing the passage of the working medium,

2. Partial regulation – the element is set in an intermediate position, changing the cross-section of the flow to regulate its intensity.

Advantages of Knife Gate Valve

Simplicity of design, high reliability, excellent tightness, quick response, and long service life. In addition, knife gate valves are economical and versatile, making them suitable for various industries.

Application Areas

Knife gate valves are used in the following areas:

- Pulp and paper industry: For controlling pulp flows during paper production.

- Mining industry: For working with abrasive media.

- Food industry: For pumping bulk materials.

- Sewage treatment: For controlling the flow of sewage with solid particles.

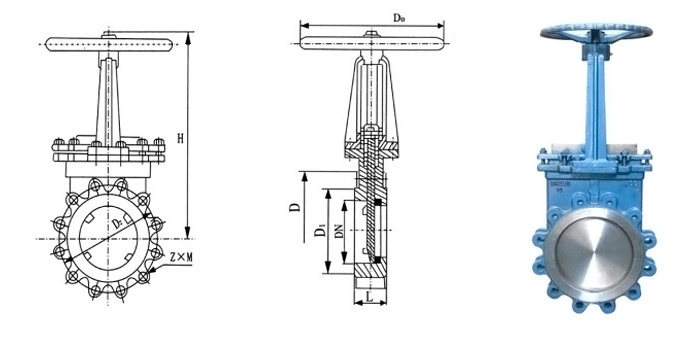

| DN | L | D | D1 | H | Z-Ød |

|---|---|---|---|---|---|

| 50 | 48 | 165 | 125 | 285 | 4-16 |

| 65 | 48 | 185 | 145 | 298 | 4-16 |

| 80 | 50 | 200 | 160 | 315 | 8-16 |

| 100 | 50 | 220 | 180 | 365 | 8-16 |

| 150 | 57 | 285 | 240 | 475 | 8-20 |

| 200 | 70 | 340 | 295 | 540 | 12-20 |

| 250 | 70 | 405 | 355 | 630 | 12-24 |

| 300 | 76 | 460 | 410 | 780 | 12-24 |

| 350 | 76 | 520 | 470 | 885 | 16-24 |

| 400 | 89 | 580 | 525 | 990 | 16-27 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | фланцевый |

| Working environment | pulp, untreated wastewater, abrasives |

| Maximum working environment temperature, °C | 120 |

| Sealing class | A |

| Body strength test, MPa | 2.4 |

| Sealing tightness test, MPa | 1.8 |

| Description | Material |

|---|---|

| Body | Steel |

| Stem | SS420 |

| Disk | AISI 321 |

| Sealing | AISI 321 |