Cast iron wedge gate valve 30ch530br, 30ch930br for manual or electric actuator Pn 10

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg | Manual actuator | Industrial electric actuator | Explosion-proof electric actuator |

|---|---|---|---|---|---|---|---|

| DN 600 | 220000.00 | 0 | 0 | 1160.0 | тип В | Н-В-06 | В-В-06 |

| DN 800 | 350000.00 | 0 | 0 | 3400.0 | тип Г | Н-Г-03 | В-Г-03 |

| DN 1000 | 500000.00 | 1 | 0 | 3840.0 | - | Н-Г-06 | В-Г-06 |

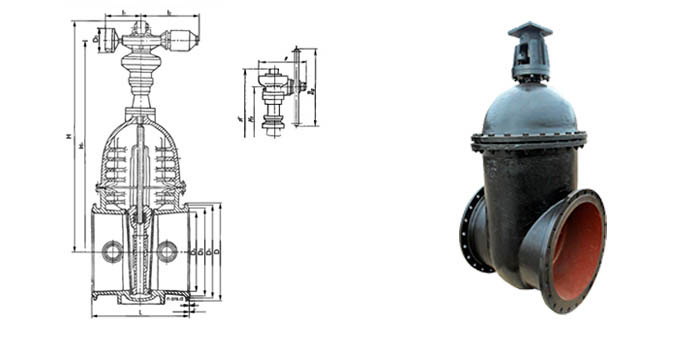

Gate valves 30ch530br, 30ch930br PN 10 are cast iron wedge gate valves with non-rising stems, designed for use as shut-off devices on pipelines. Operation is performed using a manual or electric actuator. These valves are suitable for working with media such as water, steam and other non-aggressive substances at temperatures up to +225 °C.

Design and Operating Principle

Main structural components:

- Cast iron body has two flanged ends for pipeline connection. Inside the body there are sealing rings (seats) that the gate presses against in closed position. The body forms the flow passage for the working medium.

- Bonnet is bolted to the body and forms the upper part of the valve cavity. The stem passes through the bonnet.

- Gate (wedge) - the main shut-off element that moves perpendicular to the flow direction. The gate surface (or discs) features brass sealing rings.

Stainless steel stem. One end connects to the gate, while the threaded end passes through the bonnet.

Non-rising stem is the key feature of these valves. Unlike rising stem gate valves, the stem threads are inside the valve body, in a threaded bushing connected to the gate. When rotated, the stem doesn't move up/down relative to the bonnet but only rotates, "screwing" onto the travel nut (bushing) to move the gate. This significantly reduces the valve's installation height.

- Threaded bushing (travel nut) is made of brass and attached to the gate. The stem moves along this bushing's threads during rotation.

- Stuffing box located in the upper part of the bonnet around the stem. Provides sealing at the stem passage point to prevent media leakage. Consists of packing material (e.g., graphite fiber) and packing bolts (studs) for tightening.

- Yoke assembly - contains the travel nut (for rising stems) or gearbox/actuator (for non-rising stems). In this case, since the stem is non-rising, the yoke supports the stem and provides mounting for the actuator.

Operation Features

- Gate valves 30ch530br, 30ch930br can be installed in any pipeline position except actuator-down position.

- Before installation, verify:

- Internal cavity condition;

- Smooth gate movement;

- Fastener connection reliability.

- After installation, flush the pipeline with valves open before system startup.

| DN | L | D | D1 | H | Z-Ød |

|---|---|---|---|---|---|

| 600 | 800 | 780 | 725 | 1695 | 20-30 |

| 800 | 1000 | 1010 | 950 | 2190 | 24-33 |

| 1000 | 1200 | 1220 | 1160 | 2600 | 28-33 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.0 (10) |

| Connection type | фланцевый |

| Working environment | water, steam |

| Maximum working environment temperature, °C | 225 |

| Sealing class | C |

| Body strength test, MPa | 1.5 |

| Sealing tightness test, MPa | 1.1 |

| Description | Material |

|---|---|

| Sealing rings | Brass (bronze) |

| Stem | Steel 20Сr13 |

| Shutter | Cast iron |

| Body | Cast iron |

| Bonnet | Cast iron |