×

❮

❯

![]()

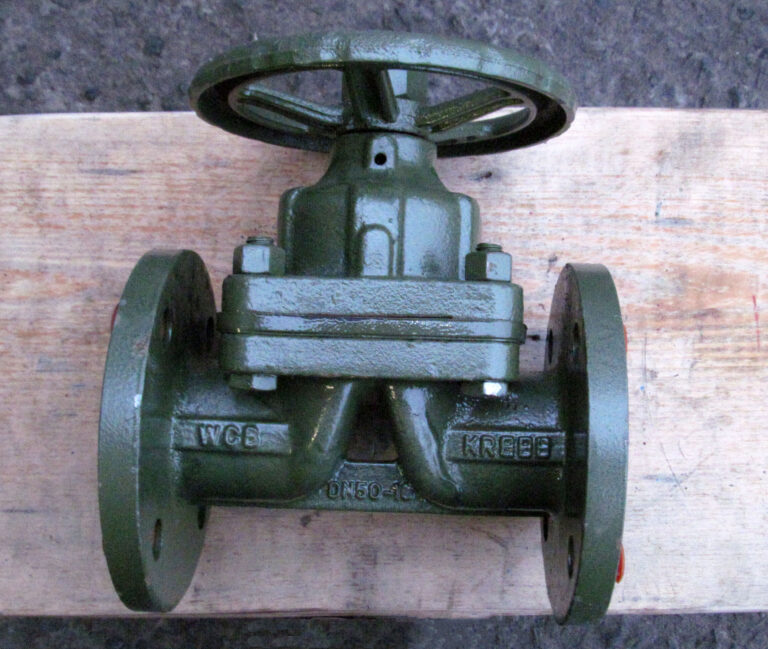

Steel diaphragm globe valve lined with PTFE Pn 10

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 40 | 5407.00 | 0 | 0 | 9.0 |

| DN 50 | 6732.00 | 0 | 0 | 12.0 |

| DN 80 | 11979.00 | 10 | 0 | 24.5 |

| DN 100 | 15708.00 | 7 | 0 | 38.5 |

| DN 150 | 36603.00 | 0 | 0 | 100.0 |

| DN 200 | 51244.00 | 0 | 0 | 149.0 |

Fluoroplastic-lined valves are shut-off devices designed for use in pipeline systems with aggressive environments. Fluoroplastic lining provides high resistance to corrosion and chemical influences, which makes such valves ideal for use in the chemical industry, pharmaceuticals and other industries where acids, alkalis or other aggressive liquids are used.

Operating principle

The valve is operated manually using a wheel:

- When the wheel is rotated clockwise, the spindle moves down, closing the flow section of the valve.

- When rotated counterclockwise, the valve opens.

Advantages of lined valves

- High corrosion resistance due to fluoroplastic lining.

- Possibility of working with a wide range of aggressive media.

- Simplicity of design and operation.

- Durability subject to operating conditions.

Application

Fluoroplastic-lined valves are widely used in the following areas:

- Chemical industry — transportation of acidic and alkaline solutions.

- Pharmaceuticals — working with alcohols and other chemicals.

- Food industry — pumping liquids without solid inclusions.

- Power engineering — cooling systems using aggressive environments.

These devices are especially in demand where a high degree of tightness and resistance to chemically active substances is required.

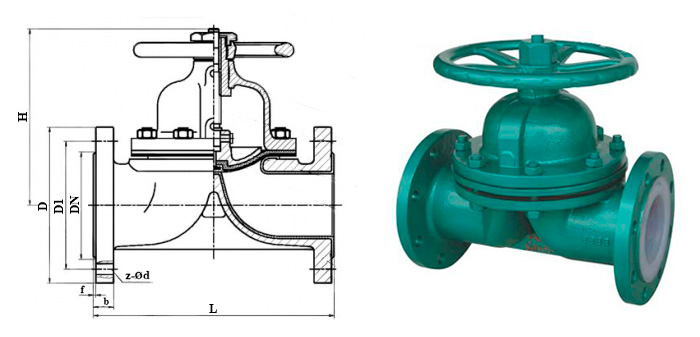

| DN | L | D | D1 | b |

|---|---|---|---|---|

| 40 | 180 | 150 | 110 | 18 |

| 50 | 210 | 165 | 125 | 20 |

| 80 | 300 | 200 | 160 | 22 |

| 100 | 350 | 220 | 180 | 24 |

| 150 | 460 | 285 | 240 | 26 |

| 200 | 570 | 340 | 295 | 28 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.0 (10) |

| Connection type | фланцевый |

| Working environment | acid, alkali, salt, aggressive liquids |

| Maximum working environment temperature, °C | 150 |

| Sealing class | A |

| Body strength test, MPa | 1.5 |

| Sealing tightness test, MPa | 1.1 |

| Description | Material |

|---|---|

| Body | Steel + FEP(F46) |

| Diaphragm | Rubber + FEP(F46) |

| Bonnet | Steel |

| Stem | Carbon steel |

| Disk | Steel |

| Wheel | Cast iron |