×

❮

❯

![]()

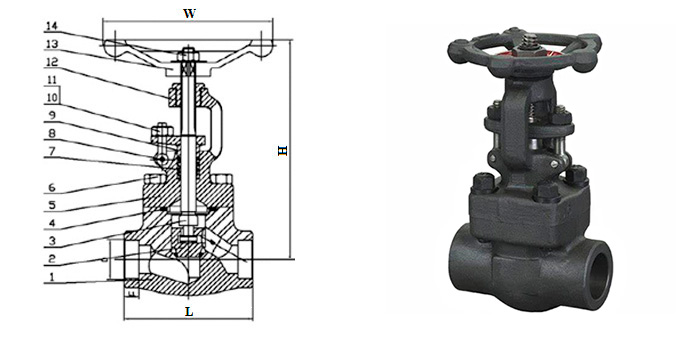

Forged steel globe valve for welding Tmax 425°C Pn 100

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 10 | 902.00 | 18 | 0 | 1.2 |

| DN 15 | 957.00 | 38 | 0 | 1.7 |

| DN 20 | 1166.00 | 40 | 0 | 2.9 |

| DN 25 | 1760.00 | 55 | 0 | 3.5 |

| DN 32 | 2420.00 | 56 | 0 | 7.1 |

| DN 40 | 3388.00 | 60 | 0 | 6.8 |

| DN 50 | 4417.00 | 33 | 0 | 11.3 |

Steel forged globe valves PN 100 are designed for installation as a shut-off mechanism on high-pressure pipelines. The body of these valves is made of A105(A105N) steel. Maximum working medium temperature is 425°C. They are connected to the pipeline by welding.

Advantages of steel forged valves PN 100

- Resistance to high pressures: Thanks to the design and quality of the material, such valves withstand significant loads.

- Durability: Long service life even under harsh operating conditions.

- Tightness: Ensuring reliable shut-off of the working medium flow.

Application of steel forged valves PN 100

- On high-pressure pipelines for transporting liquids or gases;

- In cooling or heating systems;

- At energy facilities for controlling steam or hot water flows;

- In the oil and gas industry for transporting oil, gas, or their derivatives.

| DN | L | H |

|---|---|---|

| 10 | 79 | 166 |

| 15 | 79 | 166 |

| 20 | 92 | 171 |

| 25 | 111 | 207 |

| 32 | 120 | 240 |

| 40 | 152 | 258 |

| 50 | 172 | 330 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 10.0 (100) |

| Connection type | сварной |

| Working environment | water, steam, petroleum products |

| Maximum working environment temperature, °C | 425 |

| Sealing class | A |

| Body strength test, MPa | 15 |

| Sealing tightness test, MPa | 11 |

| Description | Material |

|---|---|

| Body | A105N |

| Disk | A 182 F6A |

| Stem | A 182 F6A |

| Seal | Corrugated stainless steel + graphite |

| Bonnet | A105N |

| Bonnet bolt | A193 B7 |

| Stem sealing | Graphite |

| Pin | A276 420 A276 410 |

| Oil seal | A276 420 A276 410 |

| Oil seal bolt | A193 B7 |

| Nut | A194 2H |

| Wheel | A197 |