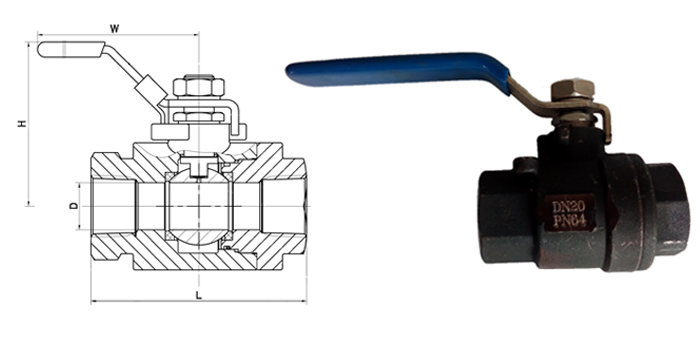

Steel full bore ball valve threaded (NPT thread) Pn 64

| Nominal diameter | Inches | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|---|

| DN 15 | 1/2" | 462.00 | 27 | 0 | 0.3 |

| DN 20 | 3/4" | 616.00 | 69 | 0 | 0.46 |

| DN 25 | 1" | 765.00 | 145 | 0 | 0.8 |

| DN 32 | 1 1/4" | 1100.00 | 45 | 0 | 1.2 |

| DN 40 | 1 1/2" | 1535.00 | 44 | 0 | 1.7 |

| DN 50 | 2" | 2063.00 | 45 | 0 | 2.7 |

Steel full-bore ball valves for PN 64 with conical NPT (National Pipe Tapered, conical inch thread with a taper of 1:16 and a profile angle of 60°) thread are shut-off valves that are widely used in various industrial and technological processes. The basic operating principle of a ball valve is to rotate the ball by 90°, which closes or opens flow of the medium. The valve body is made of carbon steel WCB (Welding Carbon Steel), and the ball is made of stainless steel AISI 304. The seal is made of RPTFE (rubber seal made of polytetrafluoroethylene), which has high chemical resistance and a low coefficient of friction.

Advantages of steel ball valves with tapered threads

- Tightness of the connection: The tapered NPT thread ensures a tight connection.

- Ease of installation: The threaded connection is easy to install without complex equipment.

- Universality of application: Suitable for a wide range of media - from water and air to chemically active substances.

- Durability: The steel body is resistant to high pressures, temperature changes and mechanical stress.

Application areas

- Oil and gas industry: Used to transport oil, gas and other hydrocarbons.

- Water supply and heating systems: Installed in hot water or steam pipelines.

- Aviation and shipbuilding industries: Used in high-pressure hydraulic systems.

Installing a ball valve with an NPT thread

To ensure a tight seal when installing a ball valve with a tapered NPT thread, it is recommended to use the following steps:

- Clean the threads from dirt before installation.

- Apply sealing tape (e.g. Teflon tape) or paste to the outer part of the thread.

- Screw the valve in by hand until it stops, then tighten it with a wrench for 1-2 turns to achieve a tight connection.

- Avoid overtightening to avoid damaging the threads or the faucet body.

| DN | L |

|---|---|

| 15 | 62 |

| 20 | 72 |

| 25 | 88 |

| 32 | 96 |

| 40 | 105 |

| 50 | 120 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 6.4 (64) |

| Connection type | муфтовый |

| Working environment | water, steam, air, gas, non-aggressive liquids |

| Maximum working environment temperature, °C | 225 |

| Description | Material |

|---|---|

| Ball | AISI 304 |

| Body | WCB steel |

| Sealing ring | RPTFE |