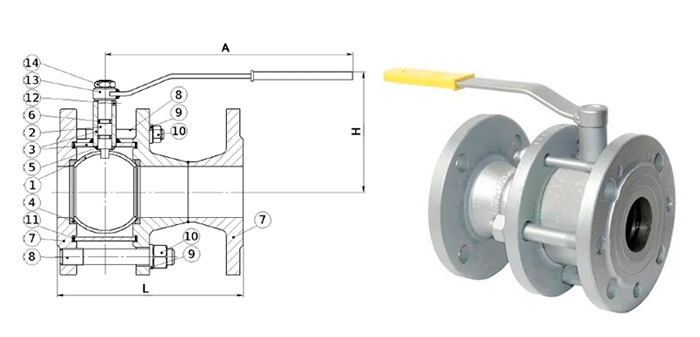

Standard bore ball valve 11s41p Pn 16

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 65/50 | 3650.00 | 0 | 0 | 12.3 |

| DN 100/80 | 5540.00 | 7 | 0 | 18.3 |

| DN 125/100 | 9000.00 | 0 | 0 | 28.7 |

| DN 150/100 | 10440.00 | 3 | 0 | 37.1 |

| DN 200/150 | 21000.00 | 0 | 0 | 60.2 |

Steel standard-bore (with reduced bore) ball valves 11s41p PN 16 are used on pipelines as shut-off devices that completely block flow of the working media. Operating principle involves rotating the ball through a 90° angle. In the open position, the axis of the ball's bore aligns with the pipeline axis, allowing media to flow freely through it. In the closed position, the ball rotates so that its wall completely blocks the flow.

Ball valve marking is deciphered as follows:

- 11 – valve type (ball valve);

- s – body material (carbon steel);

- 41 – model number;

- p – sealing material (plastic).

Design Features

- Valve repairability, as the valve features a split body design.

- The ball mechanism is made of stainless steel, preventing corrosion and extending the device's service life.

- Face-to-face dimensions and connection sizes of 11s41p ball valves DN 100, 150, 200 correspond to the dimensions of gate valves 30ch6br, 30ch6bk, 30s41nzh.

- In addition to sizes that allow gate valve replacement, this product line includes diameters with full bore that meet all requirements of gas utilities, municipal services, district heating networks, etc.

Applications

- In municipal heating systems, the 11s41p ball valve is installed to shut off heat carrier supply during maintenance work.

- At chemical plants, it's used to block flows of process liquids.

- In gas pipelines, it serves as a shut-off element to prevent gas leaks.

- At oil refineries, it's employed to control flows of crude oil or finished products.

| DN | L | D | H |

|---|---|---|---|

| 65 | 190 | 50 | 120 |

| 100 | 230 | 80 | 135 |

| 125 | 255 | 100 | 150 |

| 150 | 280 | 100 | 172 |

| 200 | 330 | 150 | 228 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | фланцевый |

| Working environment | water, petroleum products, gas |

| Maximum working environment temperature, °C | 180 |

| Sealing class | A |

| Description | Material |

|---|---|

| Lock washer | Steel 65G DSTU 8429 |

| Body seal | Polytetrafluoroethylene F4 GOST 10007 |

| Pin | Steel 45 DSTU 7809 |

| Low Nut | DSTU ISO 4035 |

| Flange | Steel 3sp DSTU 4484 |

| Stud | DSTU 7809:2015 |

| Handle | Steel 3sp DSTU 4484 |

| Ball plug | Steel 12H17 GOST 5632 |

| Stem | Steel 20H13 GOST 5632 |

| Fitting, body | Steel 20 GOST 7809 |

| Ball seal ring | Polytetrafluoroethylene F4K20 GOST 10007 |

| Stem seal | Fluorine plastic F4 GOST 10007 |

| Stem seal ring | Fluorosiloxane |

| Nut | DSTU ISO 8992 |