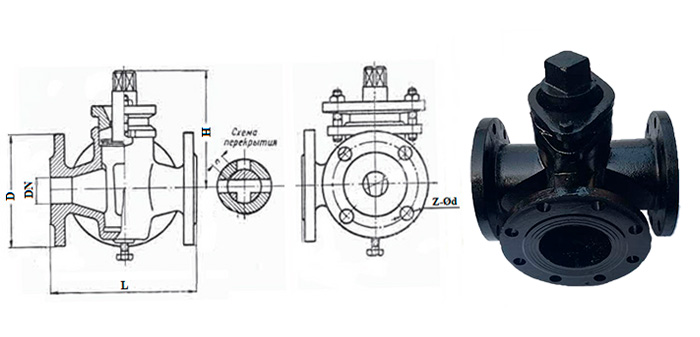

3-way plug valve 11ch18bk cast iron flanged Pn 6

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 25 | 2280.00 | 4 | 0 | 5.1 |

| DN 40 | 3540.00 | 6 | 0 | 10.4 |

| DN 50 | 4680.00 | 85 | 0 | 13.6 |

| DN 65 | 5880.00 | 18 | 0 | 20.7 |

| DN 80 | 8500.00 | 0 | 0 | 31.2 |

| DN 100 | 9840.00 | 15 | 0 | 44.6 |

11ch18bk valves PN 6.3 are three-way plug valves made of gray cast iron. They are used as a shut-off device to control the flow of the working medium in pipelines. The main purpose of the 11ch18bk valves is to redirect the flow of the working medium (water, oil) between different branch pipes of the system. This is achieved by turning the plug inside the valve body.

Design and operating principle

The 11ch18bk valve consists of the following main elements:

- Body: Made of gray cast iron.

- Plug: Made in the form of a truncated cone with a T-shaped passage hole.

- Gland: Used to seal the plug and prevent leaks.

- Control: Manually operated using a handle or a spanner.

Operating principle:

- Plug rotates around its axis inside the boby.

- Direction of flow is determined by the position of the T-shaped hole in the plug.

- There is a line on the end of the plug indicating direction of the through hole.

- Depending on the position of the plug, the flow can be directed:

- Into one of the outlet pipes;

- Simultaneously into both pipes;

- Completely blocked.

Advantages of the plug valve 11ch18bk :

- Simplicity of design and control;

- Small dimensions;

- Low hydraulic resistance;

- Durability with proper maintenance.

Disadvantages of the plug valve 11ch18b:

- Requires significant effort to turn the plug (high torque);

- Need for regular lubrication.

Installation and maintenance recommendations

- The valve can be installed in any position relative to the pipeline due to its universal design.

- Before operation, it is necessary to check the presence of grease on the sealing surfaces of the shut-off element.

- Regular inspection of the valve condition includes:

- Inspection of the tightness of the connections;

- Lubrication of the contact surfaces every three months;

- Checking functionality of the plug rotation mechanism.

If these recommendations are followed, the service life of the product is at least five years with an average resource of about 1,500 opening-closing cycles.

| DN | L | D | D1 | H | Z-Ød |

|---|---|---|---|---|---|

| 25 | 145 | 115 | 85 | 110 | 4-14 |

| 40 | 180 | 145 | 110 | 157 | 4-18 |

| 50 | 200 | 160 | 125 | 180 | 4-18 |

| 65 | 230 | 180 | 145 | 190 | 4-18 |

| 80 | 260 | 195 | 160 | 237 | 4-18 |

| 100 | 300 | 215 | 180 | 257 | 8-18 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 0.6 (6) |

| Connection type | фланцевый |

| Working environment | water, petroleum products, mineral oils |

| Maximum working environment temperature, °C | 100 |

| Sealing class | D |

| Body strength test, MPa | 1.5 |

| Sealing tightness test, MPa | 0.7 |

| Description | Material |

|---|---|

| Body | Grey cast iron |

| Bonnet | Grey cast iron |

| Sealing | Grey cast iron |