In various fields of technology, liquid viscous media are used, the movement of which through pipelines in an unheated state is difficult. To increase the fluidity of these media, they are heated and transported in a heated state. In such cases, pipeline fittings with steam heating are used. Mainly used are valves with low hydraulic resistance, in which the plug rotates around the vertical axis when opening/closing. This prevents the displacement or extrusion of the viscous medium.

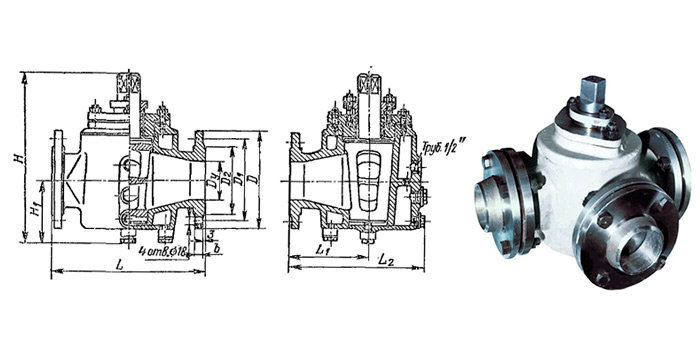

Valves 11s17bk are designed for pipelines transporting coal tar, pitch, and other crystallizing media at temperatures up to 400°C. They can be installed on the pipeline in any working position and connected to the pipeline using flanges. For steam heating, the 11s17bk valves are equipped with a jacket through which steam is supplied at a pressure of no more than 1.6 MPa and a temperature not exceeding 400°C. The seating of the valve plug is adjusted by tightening the gland. Dry asbestos is used as gland packing.

Valves 11s17bk can allow the working medium to pass through in two directions simultaneously or each separately. For this purpose, the valve bodies have three nozzles, and the plug has a T-shaped passage.