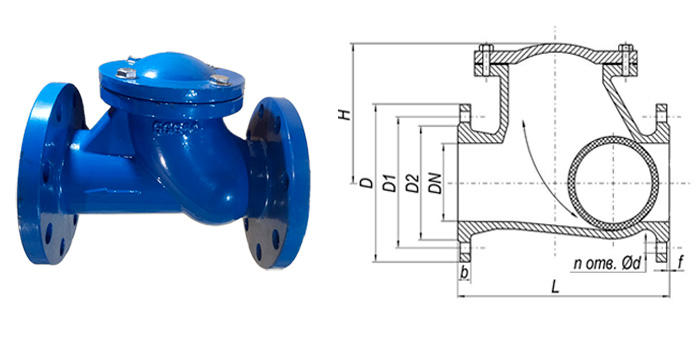

Cast Iron Flanged Ball Check Valve Pn 16

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 50 | 1500.00 | 0 | 0 | 7.0 |

| DN 65 | 2000.00 | 0 | 0 | 9.0 |

| DN 80 | 2800.00 | 5 | 0 | 11.0 |

| DN 100 | 3500.00 | 5 | 0 | 14.0 |

| DN 125 | 4800.00 | 0 | 0 | 22.0 |

| DN 150 | 6000.00 | 5 | 0 | 27.0 |

| DN 200 | 9000.00 | 5 | 0 | 40.0 |

| DN 250 | 15400.00 | 2 | 0 | 90.0 |

| DN 300 | 19700.00 | 1 | 0 | 115.0 |

Cast iron ball check valves PN 16 are designed to prevent the backflow of the working medium in pipelines where a reliable and easy-to-maintain design is required. The operating principle is based on a freely moving ball, which opens the passage under the flow pressure and instantly blocks the channel in the event of reverse flow, ensuring tight shut-off.

The valve body is made of high-strength cast iron, guaranteeing high mechanical strength and durability when used in cold and hot water supply systems, sewage systems, as well as in industrial process lines. The internal shut-off element is a ball made of cast iron and coated with a layer of NBR, ensuring tight contact with the seat and increased wear resistance. This design is particularly effective in media with inclusions or slight contamination, where traditional check valves may lose tightness or become jammed.

The valve complies with international standards:

- design and manufacturing: DIN EN 13709;

- flanged connection: JB/T79;

- testing and quality control: GB/T 13927.

The permissible operating temperature is up to 80 °C, making the valve suitable for most water supply systems, oil transfer, and technical fluid systems.

The flanged design facilitates installation and removal, enhancing maintenance convenience. The design with a minimal number of moving parts ensures high reliability and low operating costs. The ball mechanism features high flow capacity, low hydraulic resistance, and contamination resistance.

Check valves are available in the size range of DN50 to DN400 and are widely used in municipal systems, water treatment plants, pumping stations, and industrial process units. Due to the simple design and high-quality materials, the ball check valve is an optimal solution for systems requiring stable and safe operation.

| DN | L | D | D1 | D2 | b | Z-Ød |

|---|---|---|---|---|---|---|

| 50 | 222 | 160 | 125 | 100 | 16 | 4-18 |

| 65 | 230 | 180 | 145 | 120 | 18 | 4-18 |

| 80 | 260 | 200 | 160 | 135 | 18 | 8-18 |

| 100 | 282 | 220 | 180 | 155 | 20 | 8-18 |

| 125 | 315 | 250 | 210 | 185 | 22 | 8-18 |

| 150 | 350 | 285 | 240 | 210 | 22 | 8-23 |

| 200 | 400 | 340 | 295 | 265 | 22 | 12-23 |

| 250 | 498 | 405 | 355 | 320 | 24 | 12-25 |

| 300 | 555 | 460 | 410 | 375 | 26 | 12-25 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | фланцевый |

| Working environment | water, mineral oils, non-aggressive liquids |

| Maximum working environment temperature, °C | 80 |

| Description | Material |

|---|---|

| Body | Ductile iron |

| Cover | Ductile iron |

| Ball | Cast iron + NBR coating |

| Double-ended stud | CS35 (carbon steel) |

| Hex nut | CS25 (carbon steel) |