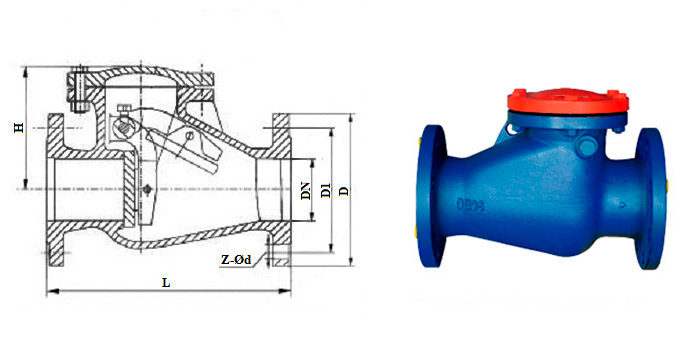

Cast iron swing flanged check valve 19ch16br Pn 10

| Nominal diameter | L, mm | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|---|

| DN 50 | 200 | 1595.00 | 2 | 0 | 13.0 |

| DN 50 | 230 | 1595.00 | 0 | 0 | 13.5 |

| DN 80 | 240 | 2772.00 | 9 | 0 | 26.0 |

| DN 80 | 310 | 2772.00 | 3 | 0 | 26.0 |

| DN 100 | 290 | 3476.00 | 8 | 0 | 30.6 |

| DN 150 | 350 | 8096.00 | 4 | 0 | 65.0 |

| DN 150 | 400 | 8096.00 | 10 | 0 | 65.0 |

| DN 150 | 480 | 8096.00 | 0 | 0 | 65.0 |

| DN 200 | 500 | 10824.00 | 10 | 0 | 90.0 |

| DN 250 | 600 | 19404.00 | 11 | 0 | 143.0 |

| DN 300 | 700 | 27060.00 | 3 | 0 | 199.5 |

| DN 400 | 900 | 51480.00 | 2 | 0 | 370.5 |

| DN 500 | 1100 | 75000.00 | 2 | 0 | 700.0 |

Cast iron flanged check valves 19ch16br PN 10 are designed to prevent backflow of the working medium in pipelines. The working medium can be water, steam, oil, oils and other oil products at temperatures up to 225°C.

Design and operating principle

The 19ch16br valves consist of a body with a shut-off element fixed inside in the form of a disk or flap. When pressure is applied, the working medium lifts the flap, opening the passage. The flap is held in the raised position due to the lifting force of the medium flow. When the pressure drops or the flow stops, the flap lowers under the influence of gravity and the pressure of the backflow, blocking the passage.

Operating conditions

The valves are installed so that the direction of the working medium coincides with the direction of the arrow on the valve body. They must be accessible for inspection and maintenance. Before installation, the valves are inspected and checked for ease of opening/closing.

Advantages

Rotary check valves are less sensitive to contamination of the medium compared to lifting analogues and ensure stable operation. They also allow the use of compensation devices to prevent hydraulic shocks.

| DN | L | D | D1 | H | Z-Ød |

|---|---|---|---|---|---|

| 50 | 200 | 160 | 125 | 125 | 4-18 |

| 50 | 230 | 160 | 125 | 125 | 4-18 |

| 80 | 240 | 195 | 160 | 152 | 4-18 |

| 80 | 310 | 195 | 160 | 152 | 4-18 |

| 100 | 290 | 215 | 180 | 168 | 8-18 |

| 150 | 350 | 280 | 240 | 215 | 8-23 |

| 150 | 400 | 280 | 240 | 215 | 8-23 |

| 150 | 480 | 280 | 240 | 215 | 8-23 |

| 200 | 500 | 335 | 295 | 243 | 8-23 |

| 250 | 600 | 390 | 350 | 265 | 12-23 |

| 300 | 700 | 440 | 400 | 350 | 12-23 |

| 400 | 900 | 565 | 515 | 430 | 16-25 |

| 500 | 1100 | 650 | 609 | 525 | 20-34 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.0 (10) |

| Connection type | фланцевый |

| Working environment | water, steam, petroleum products, mineral oils, non-aggressive liquids |

| Maximum working environment temperature, °C | 225 |

| Body strength test, MPa | 1.5 |

| Sealing tightness test, MPa | 1.1 |

| Description | Material |

|---|---|

| Body | Cast iron |

| Sealing ring | Brass |

| Disk | Cast iron |