Flanged steel lifting check valve 16s13nzh Pn 40

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 40 | 3663.00 | 0 | 0 | 11.8 |

| DN 50 | 4593.00 | 9 | 0 | 13.0 |

| DN 65 | 8250.00 | 0 | 0 | 20.0 |

| DN 80 | 10120.00 | 4 | 0 | 22.5 |

| DN 100 | 13574.00 | 6 | 0 | 44.0 |

| DN 125 | 20631.00 | 0 | 0 | 65.0 |

| DN 150 | 27280.00 | 0 | 0 | 99.0 |

| DN 200 | 45254.00 | 0 | 0 | 190.0 |

Steel flanged lift check valves 16s13nzh PN 40 are used in pipeline systems to prevent backflow of liquid and gaseous media that are neutral to the materials of the main valve parts. The valves operate automatically, without requiring external control. They consist of a body with a seat inside and a movable spool. When the working medium is supplied under the valve spool (in the direction of the arrow on the body), the flow of liquid or gas causes the spool to rise, which opens the passage for the medium. As soon as the flow stops or the pressure drops, the spool falls back onto the seat under the action of gravity and the pressure of the reverse flow, thereby preventing the movement of the medium in the opposite direction.

Application

Lift check valves 16s13nzh are widely used in various industries to protect pumping equipment from damage caused by backflow of the working medium. They also help minimize leaks in emergency situations.

Installation and maintenance

Before installing the valves, it is necessary to flush the pipeline system and check the tightness of the connections. The valves do not require regular maintenance if used correctly.

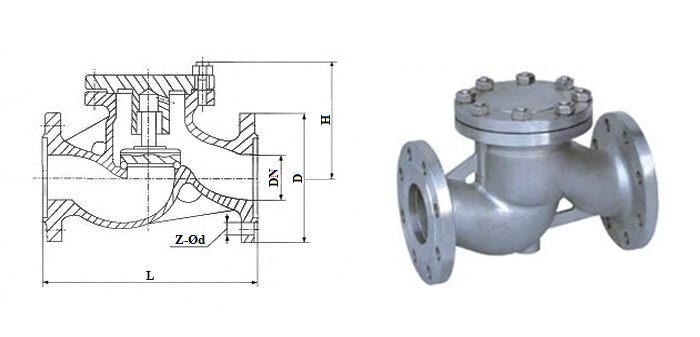

| DN | L | D | D1 | H | Z-Ød |

|---|---|---|---|---|---|

| 40 | 200 | 145 | 110 | 135 | 4-18 |

| 50 | 230 | 160 | 125 | 149 | 4-18 |

| 65 | 290 | 180 | 145 | 160 | 4-18 |

| 80 | 310 | 195 | 160 | 169 | 8-18 |

| 100 | 350 | 230 | 190 | 194 | 8-23 |

| 125 | 400 | 270 | 220 | 222 | 8-25 |

| 150 | 480 | 300 | 250 | 255 | 8-25 |

| 200 | 600 | 380 | 310 | 305 | 12-25 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 4.0 (40) |

| Connection type | фланцевый |

| Working environment | water, steam, petroleum products, gas, non-aggressive liquids |

| Maximum working environment temperature, °C | 425 |

| Body strength test, MPa | 6.15 |

| Sealing tightness test, MPa | 4.51 |

| Description | Material |

|---|---|

| Body, bonnet | Steel |

| Disk | Grey cast iron |

| Sealing ring | Stainless steel |