Check valve 16s10nzh steel lifting flanged Pn 16

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 15 | 1650.00 | 0 | 0 | 2.5 |

| DN 20 | 1799.00 | 5 | 0 | 4.0 |

| DN 25 | 1931.00 | 10 | 0 | 3.5 |

| DN 32 | 2398.00 | 10 | 0 | 5.0 |

| DN 40 | 2662.00 | 9 | 0 | 7.0 |

| DN 50 | 2926.00 | 6 | 0 | 8.0 |

| DN 65 | 4257.00 | 2 | 0 | 13.0 |

| DN 80 | 5324.00 | 8 | 0 | 20.0 |

| DN 100 | 6919.00 | 8 | 0 | 26.0 |

| DN 150 | 12645.00 | 2 | 0 | 50.0 |

Steel flanged lift check valves 16s10nzh PN 16 are designed for installation on pipelines to prevent backflow of the working medium. They are used in systems transporting water, steam, oil products and other non-aggressive media that are neutral to the materials of the main parts of the valves. The main function of the 16s10nzh valves is to automatically close when there is no flow of the working medium, which prevents the medium from moving in the opposite direction.

Design and operating principle

The 16s10nzh valves are a lifting type of check valves. Their design includes a spool that moves up or down under the influence of the force of the flow of the working medium. When the flow passes through the valve, the spool rises, opening the passage for the medium. When the supply stops or the pressure in front of the valve drops, the spool drops onto the seat under its own weight and the backflow pressure, ensuring a tight seal.

Operating conditions and installation

The valves are installed on horizontal sections of the pipeline with the cover facing up. The flow direction should match the arrow on the valve body. To ensure reliable operation, it is necessary to ensure that there are no mechanical impurities in the medium and that the flange connections are installed correctly without distortions.

Check valves 16s10nzh are important elements of engineering systems due to their ability to prevent emergency situations associated with the backflow of the working medium. Their use is especially important in systems with boiler equipment and pumps.

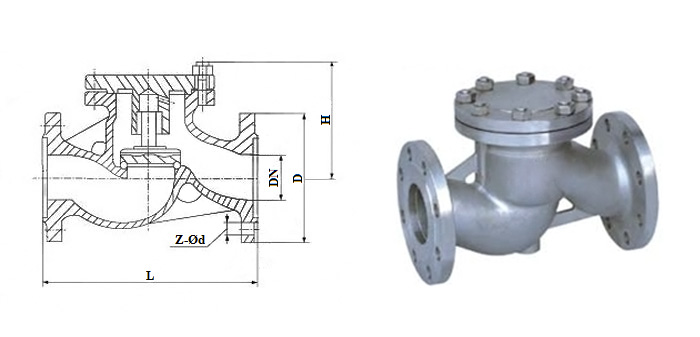

| DN | L | D | D1 | H | Z-Ød |

|---|---|---|---|---|---|

| 15 | 130 | 95 | 65 | 88 | 4-14 |

| 20 | 150 | 105 | 75 | 88 | 4-14 |

| 25 | 160 | 115 | 85 | 88 | 4-14 |

| 32 | 180 | 140 | 100 | 112 | 4-18 |

| 40 | 200 | 150 | 110 | 129 | 4-18 |

| 50 | 230 | 165 | 125 | 140 | 4-18 |

| 65 | 290 | 185 | 145 | 154 | 4-18 |

| 80 | 310 | 200 | 160 | 162 | 8-18 |

| 100 | 350 | 220 | 180 | 179 | 8-18 |

| 150 | 480 | 285 | 240 | 220 | 8-23 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | фланцевый |

| Working environment | water, steam, petroleum products, non-aggressive liquids |

| Maximum working environment temperature, °C | 425 |

| Body strength test, MPa | 2.4 |

| Sealing tightness test, MPa | 1.8 |

| Description | Material |

|---|---|

| Body, bonnet | Steel |

| Disk | Grey cast iron |

| Sealing ring | Stainless steel |