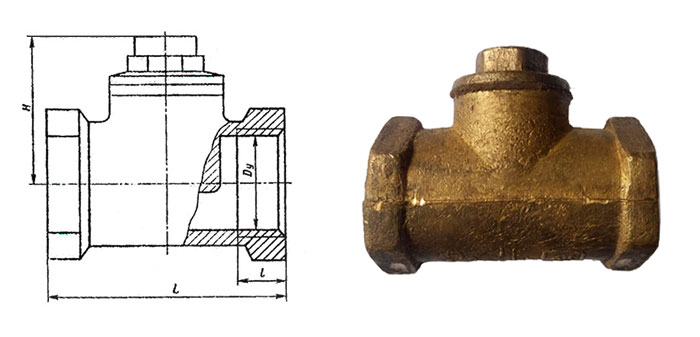

Lifting threaded check valve 16b1bk Pn 16

| Nominal diameter | Inches | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|---|

| DN 15 | 1/2" | 500.00 | 1 | 0 | 0.23 |

| DN 20 | 3/4" | 700.00 | 5 | 0 | 0.3 |

| DN 25 | 1" | 1000.00 | 22 | 0 | 0.5 |

| DN 40 | 1 1/2" | 1800.00 | 20 | 0 | 1.43 |

| DN 50 | 2" | 2500.00 | 5 | 0 | 2.0 |

Lifting check valves 16b1bk PN 16 are designed to prevent backflow of the working medium (water, steam) in pipelines. They function automatically due to the effect of the working medium pressure on the spool. The main task of the 16b1bk valves is to protect pipeline systems from unwanted backflow, which helps to increase the service life of the equipment and prevents emergency situations.

The valves consist of the following main elements:

- Body with seat, made of brass.

- Spool on the stem, which is coaxial with the seat.

Operating principle

- When there is no pressure in the system, the spool is in the closed position on the seat under the influence of gravity.

- When the working medium enters the valve, the flow pressure lifts the spool, allowing the medium to move further along the pipeline.

- If the pressure drops or the flow stops, the spool returns to its original position under the influence of gravity and the backflow pressure. This prevents the working medium from moving in the opposite direction.

Operating conditions

For the correct operation of the 16b1bk valve, the following conditions must be met:

- The valve is installed only on horizontal sections of the pipeline with the cover facing up.

- Before installation, the pipeline system must be thoroughly flushed and blown out to remove contaminants.

- The length of the straight pipe section before and after the valve must be at least ten nominal pipe diameters.

Installation recommendations

- Avoid stress and distortions at the joints with the pipeline.

- Do not use wrenches with extended handles to tighten the threads to avoid damage to the valve body.

- Provide easy access to the valve for maintenance or disassembly.

Advantages of use

- Automatic operation without the need for an external drive or control.

- High tightness when closing (minimal leaks).

- Resistance to high temperatures (up to +225°C) and pressure (up to 1.6 MPa).

- Simplicity of design ensures reliability and durability (average service life is at least 10 years).

Application area

Valves of type 16b1bk are widely used:

- In heating systems;

- In water supply;

- In pumping units;

- In industrial enterprises to protect equipment from damage due to backflow of working media.

| DN | L | H |

|---|---|---|

| 15 | 55 | 38 |

| 20 | 65 | 42 |

| 25 | 80 | 42 |

| 40 | 110 | 70 |

| 50 | 130 | 80 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | муфтовый |

| Working environment | water, steam, non-aggressive liquids |

| Maximum working environment temperature, °C | 225 |

| Description | Material |

|---|---|

| Body | Brass |

| Shutter | Brass |