Stainless steel collar flanges AISI 316Ti (10Х17Н13М2Т) GOST 12821-80 Pn 16

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 15 | 657.00 | 0 | 0 | 0.68 |

| DN 20 | 826.00 | 0 | 0 | 0.87 |

| DN 25 | 1008.00 | 0 | 0 | 1.05 |

| DN 32 | 1438.00 | 0 | 0 | 1.54 |

| DN 40 | 1651.00 | 0 | 0 | 1.85 |

| DN 50 | 2078.00 | 0 | 0 | 2.28 |

| DN 65 | 2783.00 | 0 | 0 | 3.19 |

| DN 80 | 3669.00 | 0 | 0 | 4.21 |

| DN 100 | 4281.00 | 0 | 0 | 4.9 |

| DN 125 | 5886.00 | 0 | 0 | 6.75 |

| DN 150 | 7247.00 | 0 | 0 | 8.3 |

| DN 200 | 10305.00 | 0 | 0 | 11.79 |

| DN 250 | 15226.00 | 0 | 0 | 17.36 |

| DN 300 | 19874.00 | 0 | 0 | 22.76 |

| DN 350 | 32468.00 | 0 | 0 | 32.0 |

| DN 400 | 51136.00 | 0 | 0 | 43.0 |

| DN 500 | 68182.00 | 0 | 0 | 71.0 |

| DN 600 | 94318.00 | 0 | 0 | 99.3 |

Stainless steel collar flanges PN 16, manufactured according to the GOST 12821-80 standard of stainless steel AISI 316Ti (10Х17Н13М2Т), are designed for connecting pipelines, pipeline valves and equipment in high-pressure systems. Collar flanges have a special protrusion (collar) that ensures even distribution of the load on the connection.

Material: Stainless steel AISI 316Ti (10Х17Н13М2Т) is an austenitic class stainless steel with the addition of molybdenum, which provides high corrosion resistance, especially in aggressive environments. Due to the steel composition (chromium, nickel, molybdenum), they are resistant to acids, alkalis, and other aggressive substances, as well as withstand significant temperature fluctuations.

Application of collar flanges made of AISI 316Ti (10Х17Н13М2Т) stainless steel:

- Chemical industry: Resistance to aggressive chemical substances makes them indispensable for the transportation of reagents.

- Food industry: Stainless steel is environmentally friendly and complies with strict sanitary standards.

- Medical and pharmaceutical industries: The high hygiene of the material allows such flanges to be used in the production of medicines.

- Energy and oil and gas industry: The ability to withstand high pressure and temperature makes them suitable for main pipelines.

Advantages of collar flanges made of AISI 316Ti (10Х17Н13М2Т) stainless steel:

- High corrosion resistance: Due to the content of chromium (16-18%), nickel (12-14%) and molybdenum (2-3%), the material has excellent corrosion resistance even in sea water or acidic environments.

- Connection strength: Butt welding ensures a durable connection without the risk of leakage.

- Durability: Stainless steel retains its properties for decades of operation.

- Compliance with safety standards: GOST 12821-80 guarantees the quality of manufacture and compliance with technical requirements.

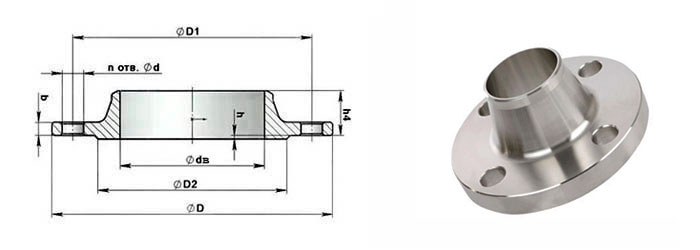

| DN | D | D1 | D2 | dв | b | Z-Ød |

|---|---|---|---|---|---|---|

| 15 | 95 | 65 | 47 | 12 | 12 | 4-12 |

| 20 | 105 | 75 | 58 | 18 | 12 | 4-12 |

| 25 | 115 | 85 | 68 | 25 | 12 | 4-12 |

| 32 | 135 | 100 | 78 | 31 | 13 | 4-16 |

| 40 | 145 | 110 | 88 | 38 | 13 | 4-16 |

| 50 | 160 | 125 | 102 | 49 | 13 | 4-16 |

| 65 | 180 | 145 | 122 | 66 | 15 | 4-16 |

| 80 | 195 | 160 | 133 | 78 | 17 | 8-16 |

| 100 | 215 | 180 | 158 | 96 | 17 | 8-16 |

| 125 | 245 | 210 | 184 | 121 | 19 | 8-16 |

| 150 | 280 | 240 | 212 | 146 | 19 | 8-20 |

| 200 | 335 | 295 | 268 | 202 | 21 | 12-20 |

| 250 | 405 | 355 | 320 | 254 | 23 | 12-24 |

| 300 | 460 | 410 | 370 | 303 | 24 | 12-24 |

| 350 | 520 | 470 | 430 | 351 | 28 | 16-24 |

| 400 | 580 | 525 | 482 | 398 | 32 | 16-27 |

| 500 | 710 | 650 | 585 | 501 | 38 | 20-30 |

| 600 | 840 | 770 | 685 | 602 | 41 | 20-33 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | приварной встык |

| Design features | воротниковый |

| Execution | 1 |

| Working environment | water, petroleum products, acid, alkali, aggressive liquids |

| Maximum working environment temperature, °C | 450 |

| Description | Material |

|---|---|

| Flange | AISI 316Ti (10Х17Н13М2Т) |