Steel flanged sediment filter Pn 16

| Nominal diameter | Price, UAH without VAT | Availability in warehouse, pcs. | Reserve, pcs. | Weight, kg |

|---|---|---|---|---|

| DN 50 | 2376.00 | 7 | 0 | 7.58 |

| DN 65 | 3828.00 | 0 | 0 | 12.68 |

| DN 80 | 4356.00 | 8 | 0 | 15.5 |

| DN 100 | 7260.00 | 7 | 0 | 17.25 |

| DN 125 | 9240.00 | 0 | 0 | 22.25 |

| DN 150 | 11220.00 | 1 | 0 | 31.5 |

| DN 200 | 18200.00 | 1 | 0 | 48.0 |

Steel sediment filters are devices designed to clean working environments from mechanical impurities. They are used in water supply, gas supply, heating systems, as well as in industrial pipelines to protect equipment from contamination. The main task of filters is to prevent dirt particles or other solids from entering the equipment, which helps to extend its service life and improve the efficiency of the system.

This type of filter is used both in enterprises (in industry) and in domestic conditions.

In industrial systems, it performs two main functions:

- Cleaning the working environment (e.g. water, gas, oil).

- Protecting equipment from damage due to foreign particles.

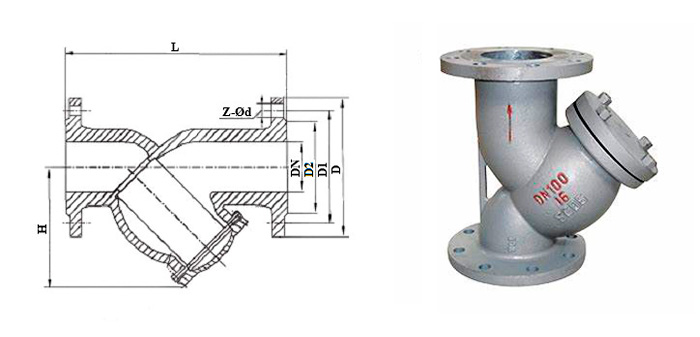

Design

Flanged steel sediment filter consists of the following main parts:

- Body: made of steel, which ensures strength and durability.

- Bonnet: closes the body and provides access to internal elements for maintenance.

- Filter mesh: made of stainless steel (AISI 304) to ensure a high degree of purification and corrosion resistance.

Applications

- Industry:

- Water purification in water supply systems.

- Gas filtration in gas mains.

- Use in the oil industry.

- Use in food industry enterprises.

- Household systems:

- Installation in heating systems to prevent clogging of radiators and boilers.

- Use in water supply systems to clean water from mechanical impurities.

- Specialized systems:

- Systems with high requirements for temperature conditions (up to +425°C).

Advantages of steel sediment filters

- High strength of the body due to the use of steel.

- Resistance to high temperatures (up to +425°C).

- Durability due to the use of stainless steel for the filter element mesh.

- Versatility – can be used with various media (water, steam, gas, oil).

- Easy installation due to flange connection.

Features of operation

To ensure reliable operation of the filter, the following recommendations must be followed:

- Regularly perform maintenance – clean the filter element mesh from accumulated contaminants.

- Install the filter according to the manufacturer's technical requirements – take into account the direction of the flow of the working medium (indicated by an arrow on the body).

Steel sediment filters are an important element of pipeline systems both in industry and in everyday life. They provide protection of equipment from damage by mechanical impurities and help to increase the efficiency of the entire system.

| DN | L | D | D1 | D2 |

|---|---|---|---|---|

| 50 | 220 | 190 | 125 | 100 |

| 65 | 250 | 180 | 145 | 120 |

| 80 | 280 | 195 | 160 | 135 |

| 100 | 310 | 215 | 180 | 155 |

| 125 | 350 | 245 | 210 | 185 |

| 150 | 380 | 280 | 240 | 210 |

| 200 | 500 | 340 | 295 | 266 |

| Parameter name | Indicator |

|---|---|

| Nominal pressure PN, MPa (kgf/cm²) | 1.6 (16) |

| Connection type | фланцевый |

| Working environment | water, steam, petroleum products, gas, non-aggressive liquids |

| Maximum working environment temperature, °C | 425 |

| Body strength test, MPa | 2.4 |

| Description | Material |

|---|---|

| Body | Carbon Steel WCB |

| Filter | AISI 304 |

| Bonnet | Carbon Steel WCB |

| Seal | Corrugated SS+graphite |